Time:2025-06-05 16:10:19

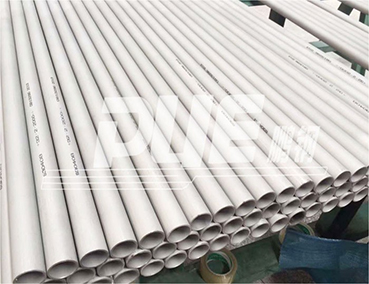

Stainless steel seamless pipes have to peel several layers from ingot to finished product.

First, heat the 304 and 316L stainless steel ingots to more than 1200 degrees to soften them, and then use a tapered roller piercing machine to punch out a hollow rough tube.

The hot-rolled pipe is directly rolled on a three-roller oblique rolling mill, and the wall thickness can be reduced to more than 2.5mm, which is suitable for large-diameter oil pipelines. If you want to make thin pipes for precision medical equipment, you have to cold draw. Use a mold to pull the pipe into a 6mm small pipe at room temperature, and anneal it repeatedly to eliminate stress, otherwise it will easily crack.

The pickling process is more troublesome. Use hydrofluoric acid and nitric acid to gnaw off the oxide scale, and then use a high-pressure water gun to rinse it inside and out, otherwise the surface will be full of pitting. The cold-rolled pipe must also pass the metal flaw detector and ultrasonic bang bang scan to see if there are any hidden scratches. Only qualified ones can be polished to a mirror finish before leaving the factory. The most valuable material is 316L. With a little molybdenum, it can't even be corroded by seawater. The reactors in chemical plants are all made of this material.